News

Broadwell Air Dome

Site

/uploads/image/677267645dfcf.png

Overseas warehousing is becoming core infrastructure for global expansion — yet companies still face slow permitting, long construction cycles, high costs, tightening environmental standards, and limited flexibility when demand or locations change. This article introduces Broadwell air dome warehouses: a fast-to-deploy, column-free, fully enclosed solution designed to reduce Capex and Opex, improve dust-control compliance, withstand extreme weather, and enable relocation and reuse. It also outlines ideal use cases — from peak-season overflow and bulk-material storage to “storage + processing” facilities and highly regulated industries.

Site

/uploads/image/677267645dfcf.png

Overseas warehousing is becoming core infrastructure for global expansion — yet companies still face slow permitting, long construction cycles, high costs, tightening environmental standards, and limited flexibility when demand or locations change. This article introduces Broadwell air dome warehouses: a fast-to-deploy, column-free, fully enclosed solution designed to reduce Capex and Opex, improve dust-control compliance, withstand extreme weather, and enable relocation and reuse. It also outlines ideal use cases — from peak-season overflow and bulk-material storage to “storage + processing” facilities and highly regulated industries.

Air Dome 101 | How Can Global-Minded Companies Quickly Build Overseas Warehousing Infrastructure?

Views: 257

Author: Broadwell Air Dome

Publish Time: 2026-01-30

Origin: Site

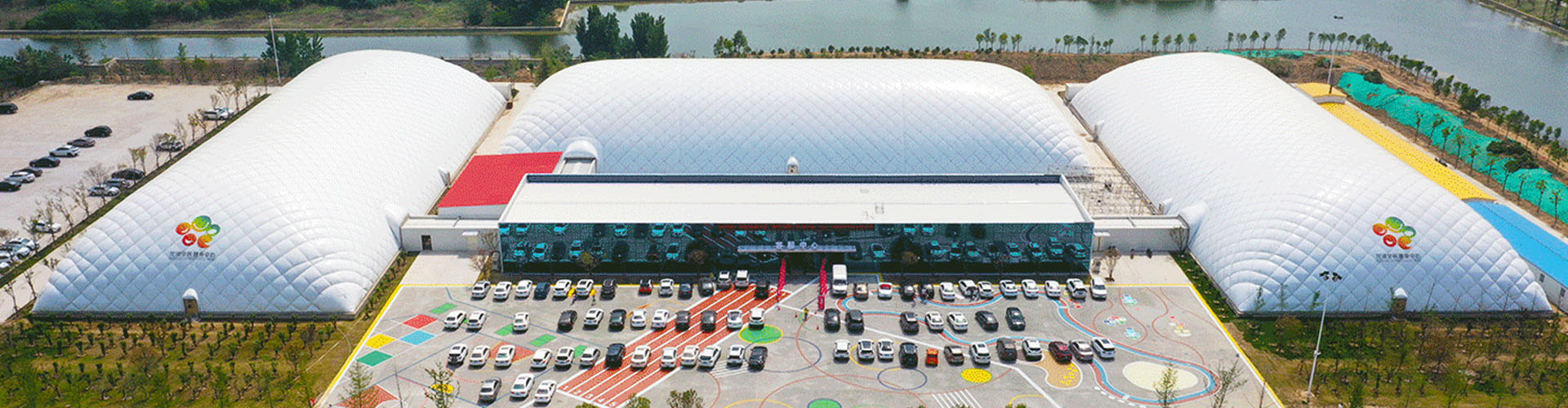

Overseas warehouses are evolving from “e-commerce forward warehouses” into a multi-industry warehousing infrastructure that supports global expansion across industries and the localization of manufacturing. When establishing warehouses abroad, companies often face the same set of challenges: lengthy approval and construction timelines, high labor and material costs, mounting environmental compliance pressure, difficulty expanding capacity during peak seasons, and sunk costs caused by site relocation. The market urgently needs a new warehousing solution that can systematically address these challenges.

What Is an Air Dome Warehouse?

An air dome warehouse uses architectural membrane materials as the building envelope. By continuously supplying air to create a slight positive pressure, the structure is formed and maintained. Because it does not rely on a conventional beam-and-column system, it enables a large-span, column-free continuous space. With advantages such as rapid deployment, modular disassembly and relocation, low maintenance, and controllable costs, air dome warehouses are becoming a preferred choice for many companies going global to solve overseas warehousing challenges.

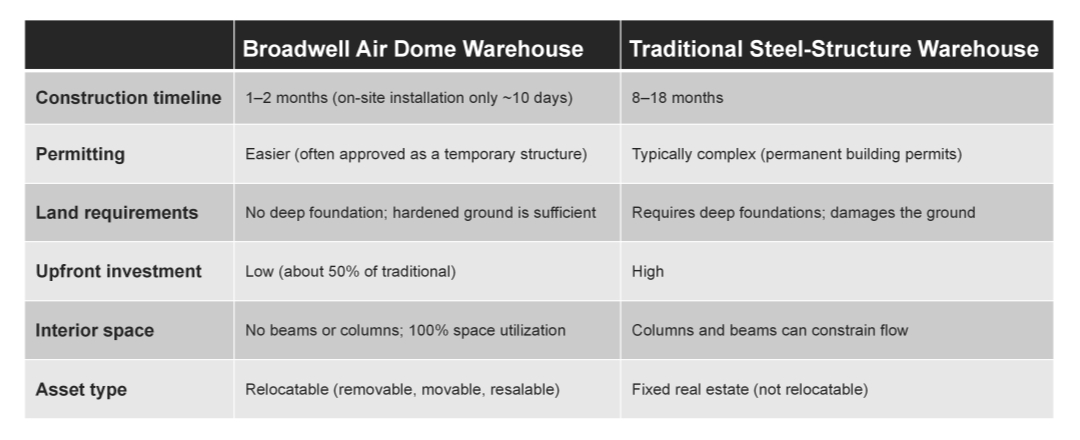

Faster Construction: 90% Shorter Delivery Time

Air dome warehouses are primarily built through 90% factory prefabrication plus on-site assembly. With minimal wet work and lower organizational complexity, overall delivery is significantly faster. For businesses, earlier commissioning means earlier throughput capacity and cash flow. Broadwell Air Dome operates two production bases with a combined capacity of 10 million m² and strong global delivery capabilities. The Yancheng production base is close to Yancheng Port, making exports especially convenient and fast.

Broadwell Yancheng Production Base (Jiangsu Province)

Lower Upfront Investment: Capex Reduced by 30%–90%

Compared with traditional warehouses, air dome warehouses typically reduce total construction costs by 30%–90%. The unit cost per square meter decreases as the total area increases. For overseas warehouse networks that must be replicated across multiple countries and locations, this means lower per-area investment and faster network rollout.

Column-Free Space: Maximizing Storage Capacity and Efficiency

A column-free interior makes pallet layout, sorting, loading/unloading, and heavy equipment movement smoother — improving storage utilization. Beyond e-commerce distribution, it is also ideal for bulk cargo transshipment, resource stockpiling, and new energy components —scenarios that require uninterrupted working surfaces. Broadwell air dome storage warehouses can achieve spans of over 200 m, meeting large-space and high-volume storage requirements.

RRS Logistics Air Dome Warehouse, Shandong — providing warehousing services for the Haier Group (built by Broadwell Air Dome in 2021)

More Eco-Friendly Dust Control: “Built-In” Compliance, Fewer Retrofits

As overseas environmental regulations tighten, dust emissions and fugitive leakage are often major hurdles for acceptance and community relations. The fully enclosed structure of an air dome warehouse inherently suppresses dust escape. Broadwell air dome warehouses can reduce dust by over 90%, helping projects pass environmental acceptance on the first attempt — especially suitable for coal, mineral powder, grain, recyclable resources, and similar materials.

Jurun Building Materials Air Dome Storage Facility, Shandong (built by Broadwell Air Dome in 2022)

Safer: Built to Withstand Extreme Weather

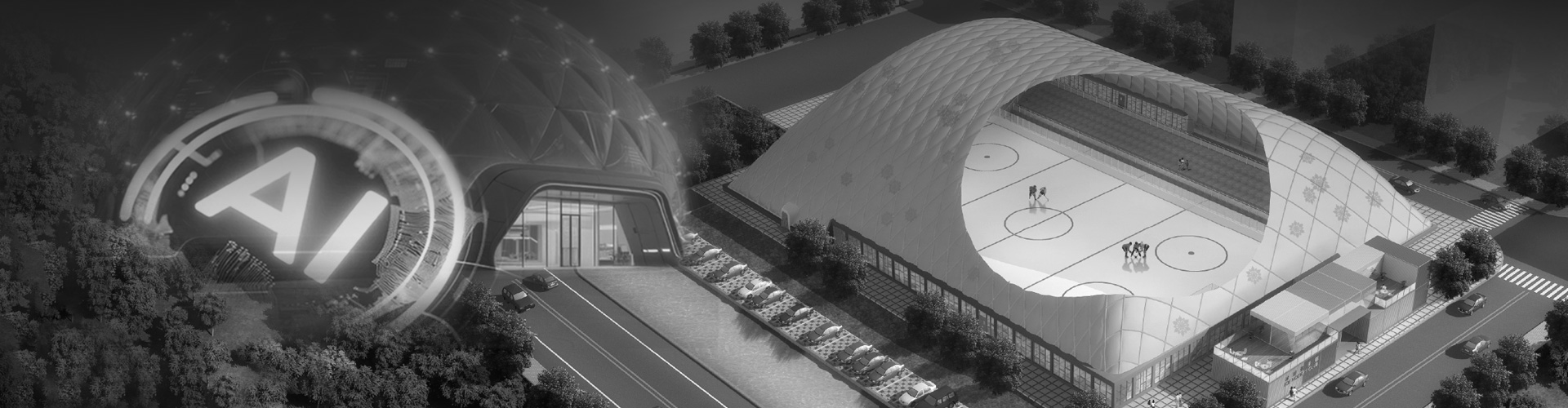

Broadwell’s proprietary patented Bias-Pro diagonal orthogonal steel cable net system provides strong wind, pressure, and disaster resistance. The cable system bears 16/17 of the membrane pressure, delivering a pressure-bearing capacity 14 times that of conventional cable technologies. It can withstand up to Category 18 typhoons and snow loads exceeding 250 kg/m².

Lower Opex: Significantly Reduced Operating and Maintenance Costs

Overseas projects often face “hard-to-repair, costly labor, and high downtime losses.” Broadwell air dome warehouses are equipped with the self-developed remote intelligent management platform, BroadCool Cloud Control, enabling 24/7 unmanned operation and reducing inspection and fault-response costs. In addition, the patented intelligent distributed control system reduces control-system risks compared with conventional air dome warehouses and saves about 50% in energy.

Relocatable and Reusable: Turning Sunk Costs into Deployable Assets

When lease terms change, port nodes are adjusted, industrial parks relocate, or demand fluctuates, an air dome warehouse can be disassembled and reused — substantially reducing sunk costs. This makes it ideal as “flexible capacity” and for temporary or phased facilities.

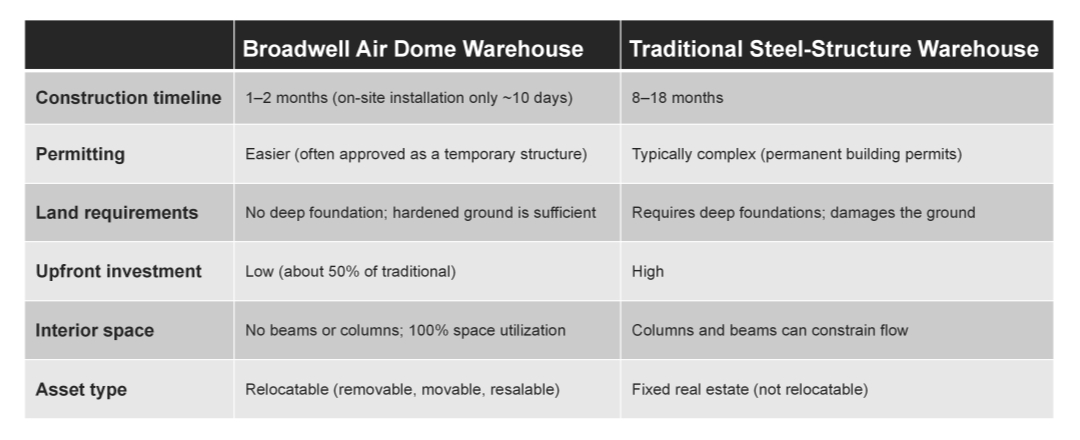

Broadwell Air Dome Warehouse vs. Traditional Warehouse: Six Key Considerations

Which Use Cases Are Best Suited for Air Dome Warehouses?

RBL Chemical Technology Co., Ltd. Air Dome Temperature-Controlled Warehouse, Shandong (built by Broadwell Air Dome in 2022)

Lighter, Faster Infrastructure for a More Dynamic Market

Competition in overseas warehousing is shifting from “whether you have a warehouse” to “whose warehouse starts up faster, costs less, stays compliant more reliably, operates with lower O&M, and can flex with market changes.” From serving benchmark domestic projects, such as those with Shenhua Group, to providing air dome warehousing services for McDonald’s and Haier Group, and delivering large bulk-material warehousing projects in South America, Broadwell has validated the reliability and forward-looking value of air dome warehousing technology across global markets. With assembly-speed delivery, outstanding lifecycle cost performance, and relocatable reusability, Broadwell air dome warehouses offer a “lightweight infrastructure” solution that better aligns with the pace of today’s overseas warehousing needs.