Ice and snow venues—especially indoor ski resorts—are inherently capital-intensive, energy-hungry, and time-consuming projects. That leads to a very practical question: without compromising functionality or user experience, can we meaningfully reduce the total cost of “building + operating” the venue?

Broadwell’s answer is yes: replace traditional reinforced-concrete or steel-frame enclosures with an air-supported structure, cutting costs across four dimensions at once—materials, civil works, construction time, and energy use.

Cost Reduction: From “Reinforced Concrete” to “Air Support”

1. Lower material costs: replace “large amounts of steel and enclosure materials” with “high-performance membrane.”

Traditional steel buildings require large quantities of steel members, purlins, roof panels, and insulation systems. Materials typically account for a high share of total cost and are highly sensitive to steel-price fluctuations.

In an air dome, the main “shell” is primarily made of an architectural membrane. With no beams or columns, the material supply chain is shorter, and overall material usage is lower.

Broadwell selects a professional membrane system tailored to ice-and-snow operating conditions, balancing strength, weather resistance, flame retardancy, and thermal insulation—providing a solid foundation for both lightweight construction and long-term operation.

2. Lower civil-work costs: a lighter superstructure means a lighter foundation and simpler construction

A steel building’s self-weight and load-transfer path typically require heavier foundations and more complex civil engineering. An air dome is much lighter overall. Broadwell’s membrane weighs only 2 kg/㎡, which simplifies ground or foundation requirements. The fully enclosed structure also reduces on-site wet trades, cutting workload by up to 90%.

3. Cost-effective ice and snow venues even in tropical regions: geography no longer multiplies cost

Building an ice and snow venue in hot, humid climates traditionally costs more—thicker envelopes, heavier equipment, and longer schedules. With an excellent thermal insulation system, an air dome keeps the extra cost of high-temperature regions within a more controllable range, making ice-and-snow formats in tropical and subtropical areas easier to deploy and replicate.

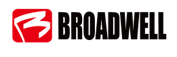

Broadwell’s technologies for insulation, dehumidification, and snowmaking in air-dome ice venues are already mature, with projects delivered in multiple southern Chinese cities.

Shenzhen Kunlun Red Star Ice Hockey Club Air-Dome Rink (Built by Broadwell in 2020)

Time Is Money: Open Earlier, Get Paid Back Earlier

More than 90% of an air dome structure is prefabricated in the factory, with fewer on-site processes and a shorter schedule. Backed by Broadwell’s two major air dome industrial parks in Yancheng, Jiangsu, and Chifeng, Inner Mongolia, with an annual capacity of over 10 million ㎡, an ice-and-snow venue can be completed in about 4 months—at least 50% faster than traditional structures.

Not Only Cheaper to Build, but Cheaper to Run: Broadwell Air-Dome Ice Venues Are More Energy-Efficient

What truly “burns money” in an ice venue is often not construction, but long-term operation. With the same indoor temperature and humidity targets, Broadwell air domes maintain conditions with significantly lower energy consumption.

Broadwell’s R-Plus thermal insulation system can achieve an overall building insulation performance of R20, reducing total energy use by more than 80%. Its proprietary thermal-bridge-prevention membrane processing improves insulation by 20%. A patented combined air-duct system allows supply-air temperature control, cutting energy use during non-operating hours by over 90%.

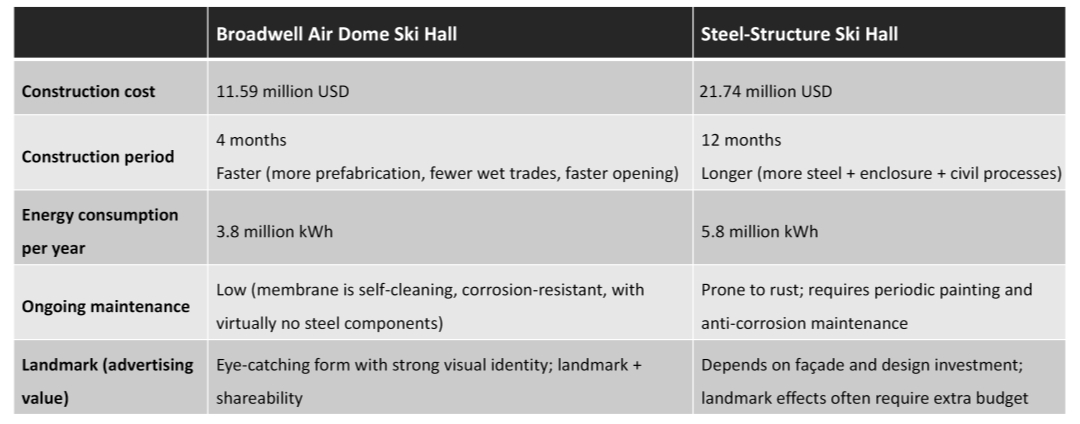

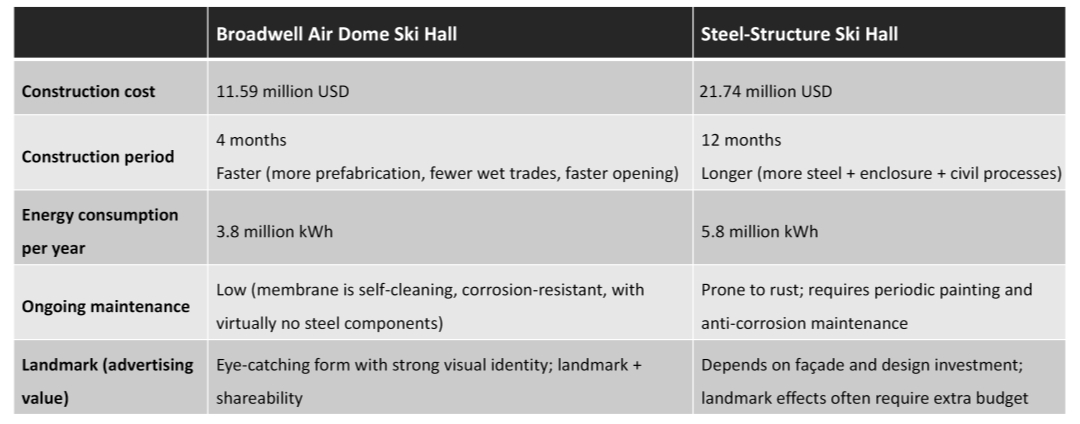

Broadwell Air Dome Ski Hall vs. Steel-Structure Ski Hall: How Much Can You Save?

Take an 80 m × 200 m = 16,000 ㎡ ski hall in China as an example. Here’s a side-by-side comparison:

The construction-cost difference is:

21.74 million − 11.59 million = 10.15 million USD

That means on the build side alone, Broadwell significantly reduces the heavy asset burden at this scale—not yet counting earlier revenue from faster opening or long-term operating savings from higher efficiency.

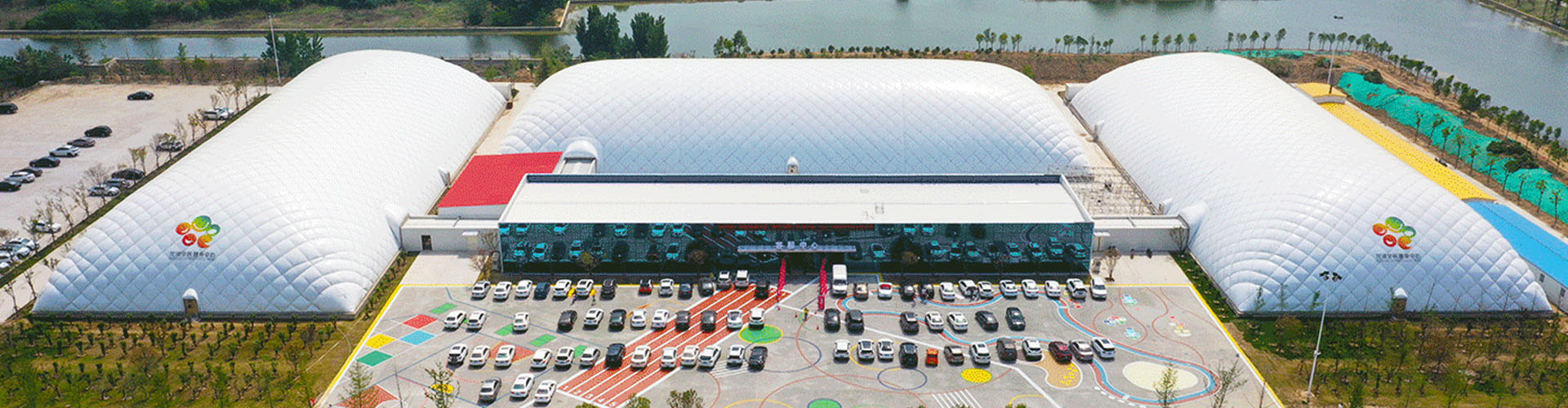

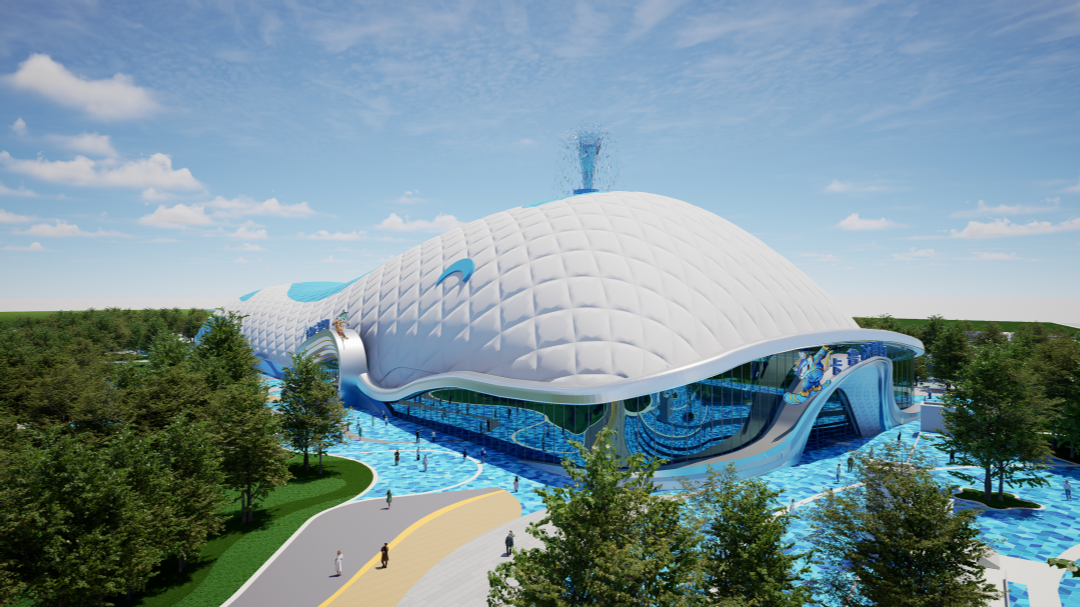

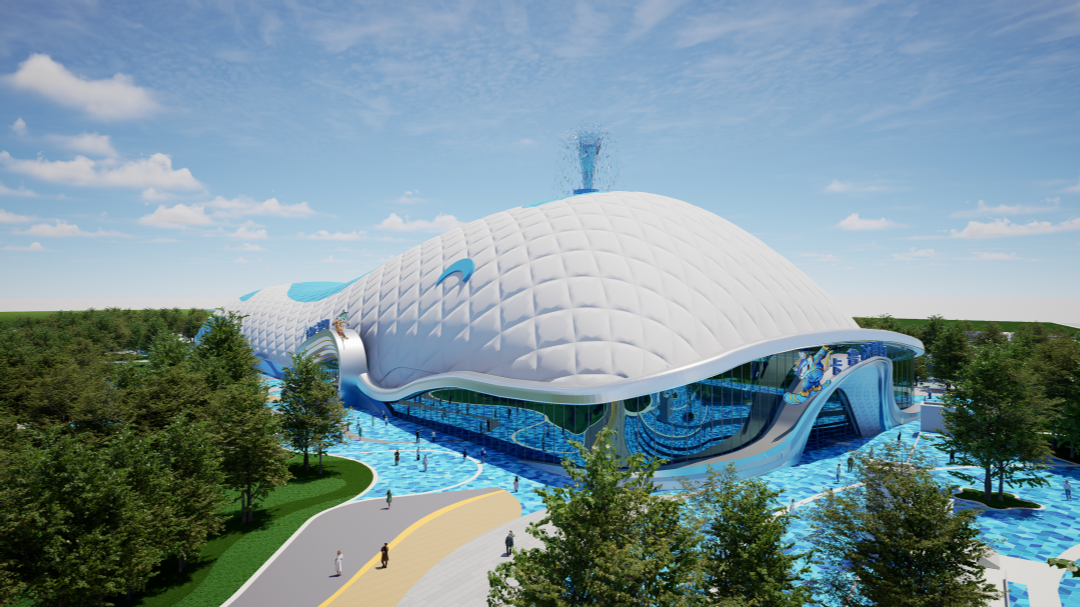

Karoo Ice & Snow World Phase II—unique whale-shaped design (Broadwell project under construction)

In Closing: What You Save Isn’t Just Money—It’s Predictability

With huge growth potential in the global ice-and-snow sports market, the key to success for indoor ice-and-snow venues is often not “can it be built,” but how fast it can be delivered, how efficiently it can be operated, and how stable the cash flow can be.

Broadwell’s core value is turning the heavy asset segments of the ice-and-snow industry into a more controllable, more efficient operating model—by reducing cost across materials, civil works, schedule, and energy.

As a pioneer and leader in air-dome ice-and-snow applications, Broadwell built China’s first air-dome ice hockey rink in 2015, created a professional skating club for world champion Chen Lu, and enabled Sanya’s “Ice in the South” air-dome venue cluster to break through climate limitations. Broadwell air domes have achieved full geographic coverage and extensive project validation. With technological innovation and proven delivery experience, we help clients move lighter, execute faster, and profit more steadily in the ice and snow sports sector. Choosing Broadwell is not just choosing an air-supported structure—it’s choosing a mature, efficient, end-to-end solution for ice-and-snow assets.