Negative Pressure Hospital

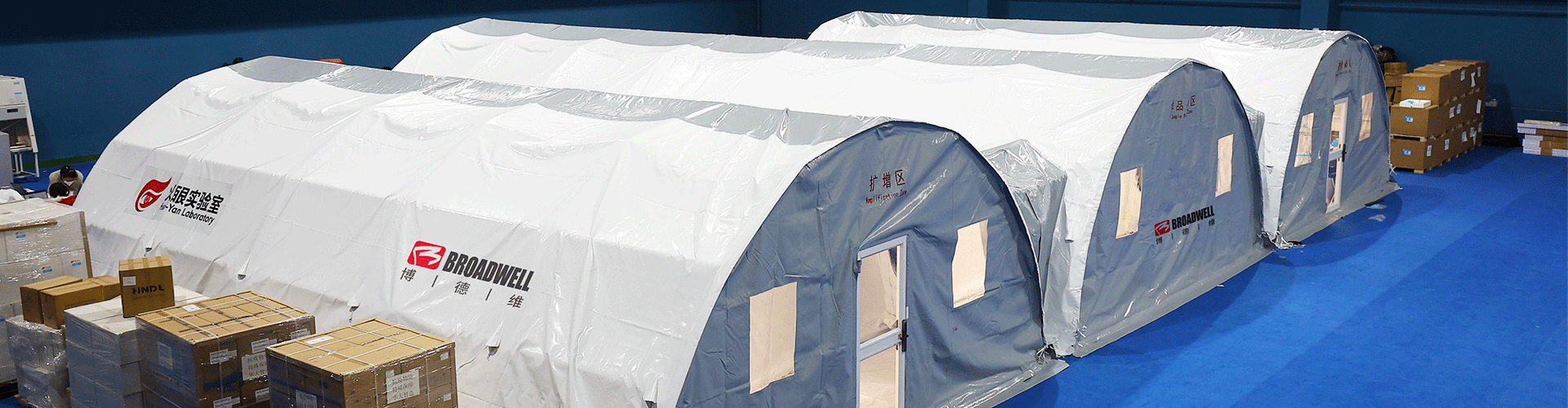

BROADWELL Negative pressure hospital is a fast setup, portable and modular multi-purpose shelter system issued by Broadwell R&D center. It can be widely used in negative pressure hospital, nucleic acid laboratory, military emergency, disaster relief emergency, temporary accommodation and other fields.

With the features of quick installation, convenient transportation, economical and practical products, BROADCAMP can meet the customized requirements of customers in all aspects, and help customers save time and improve efficiency!

Advantages

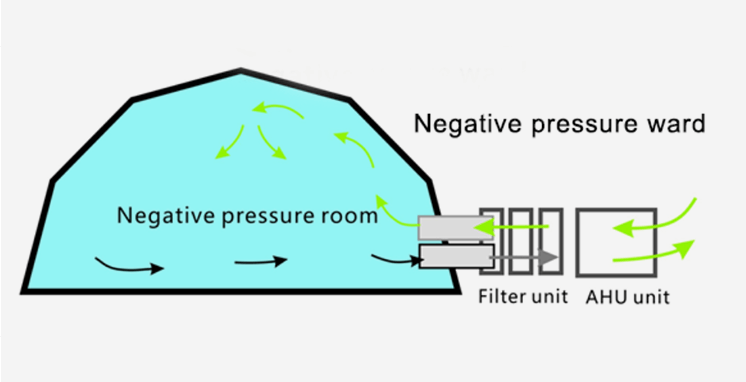

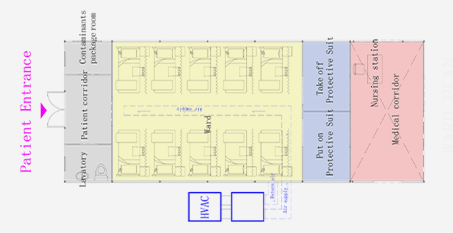

Negative pressure ward

It can effectively prevent polluted air leakage and is suitable for the treatment of respiratory infectious diseases.

Dual Isolation

Patients and doctors are isolated separately, and a Neutral Zone is created to prevent the virus from spreading between patients and doctors. One AHU unit for each ward, polluted air is discharged to the outdoors only after strict filtration and disinfection.

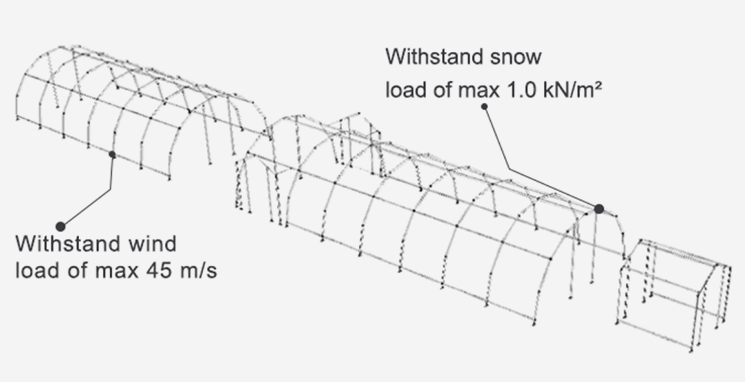

Quickly Assembly Designed High Strength Aluminum Frame

48 hours to complete a 100-bed hospital, Saving time for saving lives ——BROADCAMP unique technology—quickly unfolding aluminum arch and quickly plug design.

——Internal frame consists of square tubes made up of high-strength aluminum alloy, with a diaphragm effect. As a result, our tent has high enough strength to sustain extreme weather such as blizzards, storms.

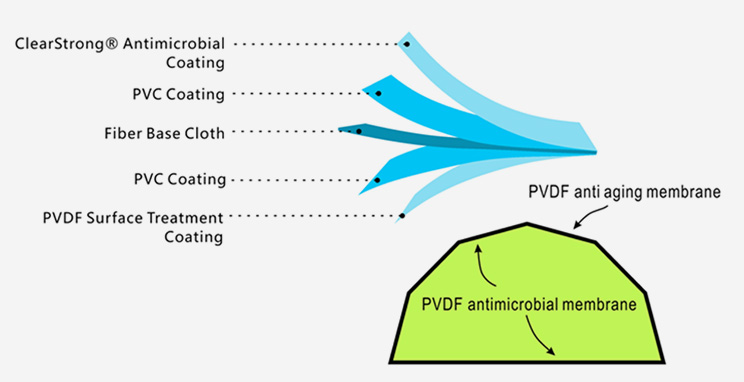

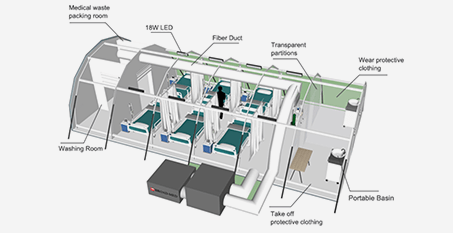

New Antimicrobial Material ClearStrong®

1. The main body uses a white PVDF-coated self-cleaning anti-aging membrane, corridor uses grey.

2. Interior roof and floor use white ClearStrong® membrane.

3. Membrane application environment temperature: -40︒C to 70︒C.

4. Membrane tensile strength >2500N/5cm.

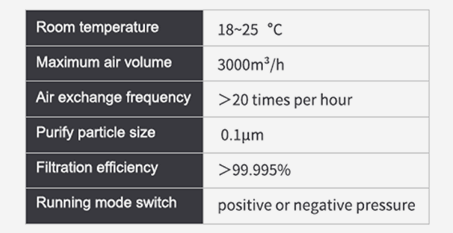

Integrated AHU Unit

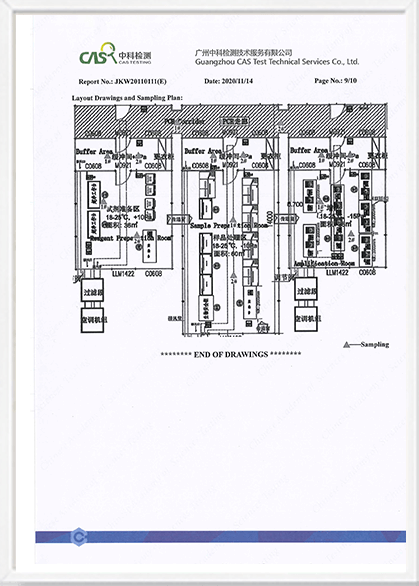

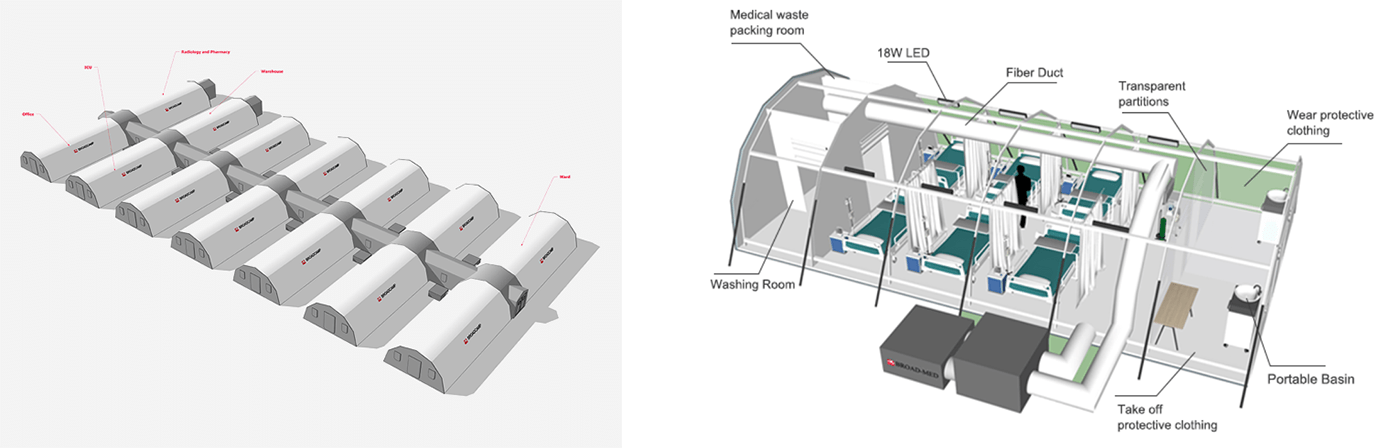

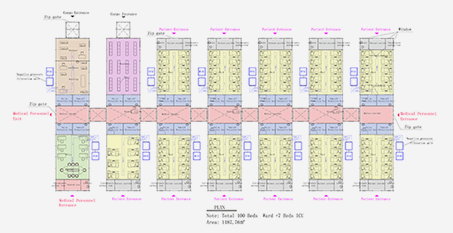

This hospital consists of 14 unit tents,

Dividing the functional zone includes 11 isolating wards,

1 warehouse, 1 office, and 1 treatment unit

( includes pharmacy, laboratory, and radiology room).

Configuration list

| NO. | ITEM | DESCRIPTION | AMOUNT | UNIT | NOTE | ||

|---|---|---|---|---|---|---|---|

| 1 | Aluminum Alloy Frame System | ||||||

| 1-1 | Aluminum Alloy Frame | 1 | package | ||||

| 2 | Fabric Envelope System | ||||||

| 2-1 | Outer Fabric | Construct membrane,2500N/5cm | 1 | package | |||

| 2-2 | Inner Fabric | PVDF self-cleaning membrane, 2500N/5cm | 1 | package | |||

| 2-3 | Ground Fabric | ClearStrong® antibacterial membrane, 2500N/5cm | 1 | package | |||

| 3 | Electronic Device and Accessories | ||||||

| 3-1 | LED Lighting | 18W, 220V, 50hz/60Hz (Optional) | 10 | pcs | |||

| 3-2 | Accessories | C-type clamp, with fastening bolt | 1 | set | |||

| 3-3 | Industrial socket box | Indoor application, black, IP44 | 1 | set | |||

| 3-4 | Industrial socket box | 6 jacks socket, white, IP44 | 1 | set | |||

| 3-5 | Portable socket | 6 jacks socket, white, IP44 | 1 | pc | |||

| 3-6 | Connecting cables | Power cable, plug-in cable, light cable | 1 | package | |||

| 3-7 | Package | Oxford waterproof fabric bag, for frame and membrane, transport case | 1 | package | |||

| 3-8 | Anchorage Components | Anchor nail, with fiber rope and buckle | 1 | package | |||

| 3-9 | Attached Accessories | User manual, tools bag, and installation package | 1 | package | |||

| A | Module A | 12*6m Module | 7 | set | The components for each Module A/B, including items 1-3 above | ||

| B | Module B | 15*6m Module | 7 | set | |||

| C | Module C | 2.4*2.8 Module(Joint Channel) | 6 | set | |||

| C1 | Aluminum Alloy Frame | Dimension: 2.4*2.8m | 1 | set | |||

| C2 | Fabric Package | ||||||

| D | Integrated AHU unit | 14 | set | ||||

| D1 | HVAC System | Cooling capacity 18 kW, power input 12kW, air volume 3000 m3/h | 1 | set | |||

| D2 | Purification Section | G4+F8+H14 trible filter, (G4 filter inside AHU unit) | |||||

| D3 | Fiber Cloth Duct | Ø400, with hanging belt | 1 | set | |||

| D4 | AHU cable | HO7RN-F-5*6 mm | 1 | set | |||

| E | Customized Components | ||||||

| E1 | Designed Logo | Special design logo as the customer required, pasted on the membrane or door panel | 1 | Package | |||

| 1. Aluminium Alloy Frame | ||||||

| 1-1 | Aluminium Alloy Frame | 1187.76 | sqm | 1750*600*260*15 2100*200*260*12 3100*210*270 2350*200*250*2 2900*200*200 1700*200*250 1300*200*250 | 4590 | The Dimension here is for each set of wards (two-unit ward), the whole system has 7 sets. Can be stacked. |

|---|---|---|---|---|---|---|

| 2. Fabric Envelope System | ||||||

| 2-1 | Outer Fabric | 1187.76 | sqm | 1500*2000*2000 | 1140 | |

| 2-2 | Inner Fabric | 1187.76 | sqm | 114 | ||

| 2-3 | Ground Fabric | 1187.76 | sqm | 1130 | ||

| 3. Integrated AHU System | ||||||

| 3-1 | Integrated AHU System | 13 | sets | 7340*4400*1670 | 2600 | Net Weight/Size for each single unit: HVAC Unit: L1350*W1350*H770, 20mm more with packing, weight 120kg. Purification Section: L1350*W1350*H820, 20 more with packing, weight 80kg。 Can't be stacked. |

| 4. Lighting System LED | ||||||

| 4-1 | LED Lighting | 210 | pcs | 1370*1760*400 | 130 | Can't be stacked. |

| 4-2 | Cable System | 1 | package | 1500*1500*1500 | 150 | |

| 4-3 | Accessories | 1 | package | 500*500*500 | 100 | |

| Total | 107sqm | 10980 | ||||

|

|---|

| Module A |

| 6*12*3m(W*L*H) |

| Std. Tent |

|

| Module B |

| 6*15*3m(W*L*H) |

| Std. Tent |

|

| Module C |

| 2.4*2.8*2.7m(W*L*H) |

| Channel Unit |

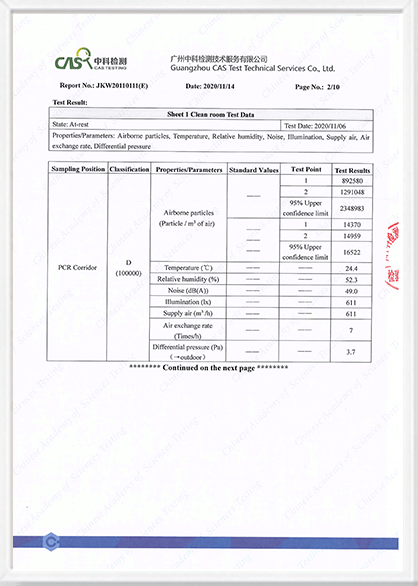

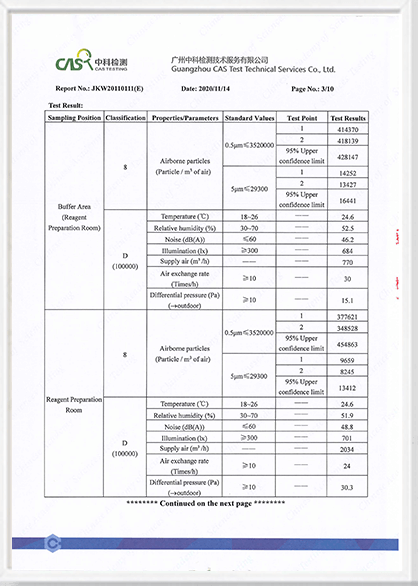

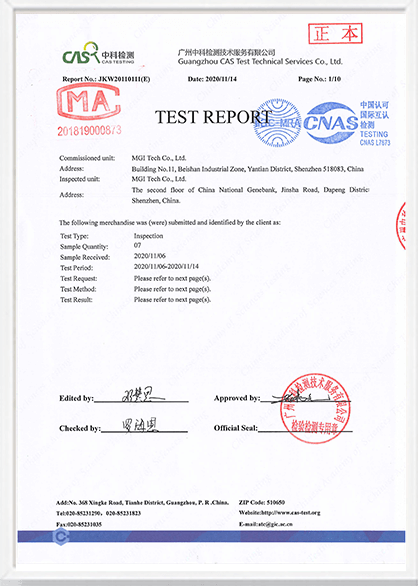

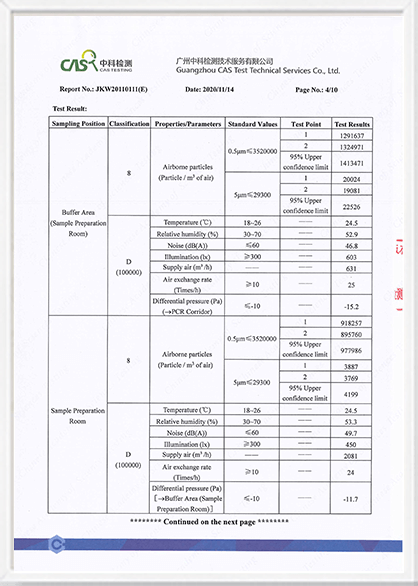

Certifications