News

Broadwell Air Dome

Site

/uploads/image/677267645dfcf.png

Site

/uploads/image/677267645dfcf.png

Innovative Air-Inflated Warehouses: Revolutionizing the Logistics Industry

Views: 1869

Author: Broadwell Air Dome

Publish Time: 2024-06-17

Origin: Site

In the rapidly evolving landscape of logistics and warehousing, air-inflated structures, or air-inflated warehouses, have emerged as a revolutionary solution. These structures offer a plethora of advantages over traditional warehouses, making them an attractive option for businesses looking to enhance efficiency, reduce costs, and quickly adapt to market demands. This article delves into the multifaceted benefits of air-inflated warehouses, highlighting their architectural flexibility, cost-effectiveness, environmental sustainability, advanced monitoring capabilities, spatial adaptability, safety features, ease of relocation, material advantages, intelligent control systems, and applicability across various industries.

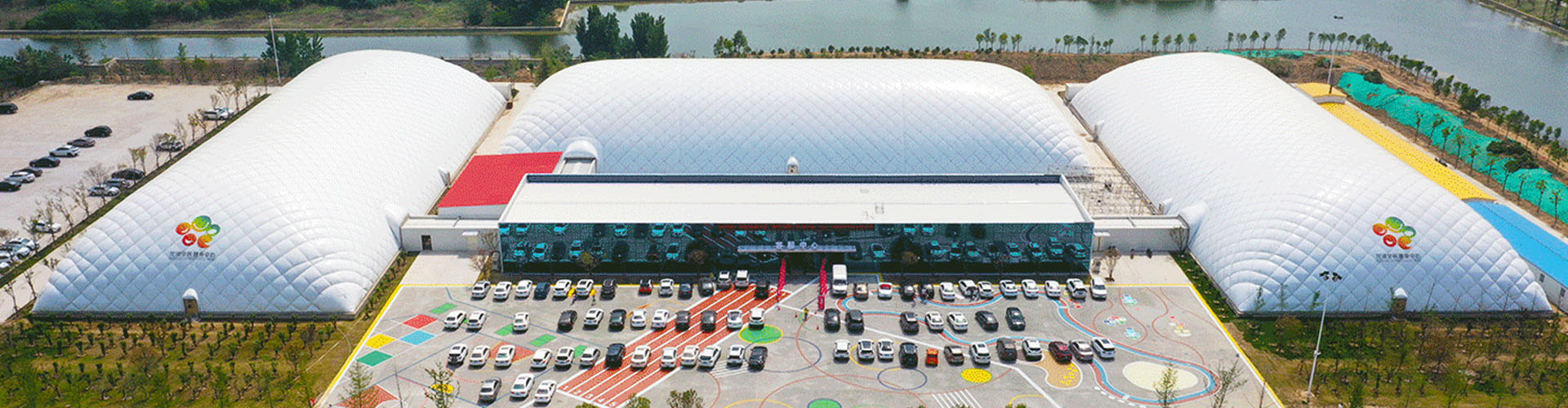

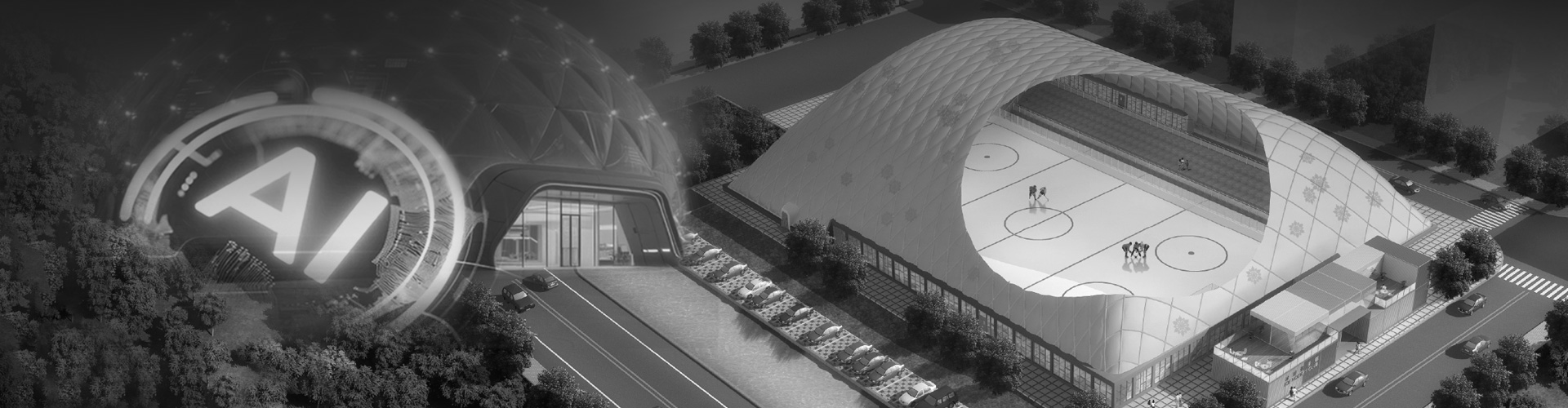

Architectural Flexibility and Rapid Deployment

One of the most significant advantages of air-inflated warehouses is their architectural flexibility and rapid deployment capability. These warehouses utilize a modular assembly process, allowing for swift construction and installation. Unlike conventional warehouses, which may take months or even years to build, air-inflated warehouses can be erected in approximately ten days. This speedy construction process enables businesses to respond promptly to market changes and shifting logistics needs, providing a strategic edge in a competitive landscape. The ability to quickly set up a functional warehouse without the extensive lead time associated with traditional construction projects is a game-changer for many industries, particularly those that experience seasonal fluctuations or sudden increases in demand.

Cost-Effectiveness and Operational Efficiency

Cost efficiency is another critical benefit of air-inflated warehouses. The construction costs of these structures are significantly lower than those of traditional buildings. Furthermore, their maintenance costs are also relatively minimal, contributing to overall reduced operational expenses. For businesses aiming to optimize their bottom line, the financial advantages of air-inflated warehouses are compelling. These cost savings can be reinvested into other areas of the business, such as technology upgrades or workforce training, enhancing overall productivity and competitiveness. The reduced financial burden associated with constructing and maintaining these warehouses makes them an economically viable option for companies of all sizes.

Environmental Sustainability and Energy Efficiency

Environmental sustainability is increasingly becoming a priority for businesses across various sectors. Air-inflated warehouses excel in this area due to their superior airtight performance, which significantly reduces the energy required for heating and cooling. Compared to traditional buildings, the energy consumption of air-inflated warehouses is only 10% to 30% of that of conventional structures. This dramatic reduction in energy use not only lowers operating costs but also minimizes the environmental footprint of warehousing operations. The reduced carbon emissions and energy consumption align with global sustainability goals, making air-inflated warehouses an eco-friendly choice. Companies committed to corporate social responsibility and environmental stewardship can benefit from the sustainable features of these innovative structures.

Advanced Monitoring and Intelligent Control Systems

The integration of advanced monitoring and intelligent control systems further enhances the appeal of air-inflated warehouses. Through mobile applications, businesses can monitor key environmental parameters such as temperature, humidity, and wind pressure in real-time, 24/7. This capability reduces management costs and increases safety by ensuring that the internal conditions are consistently optimal. Additionally, intelligent control systems allow for the automatic adjustment of these parameters, improving energy efficiency and maintaining a stable environment for stored goods. The technological sophistication of air-inflated warehouses provides a higher level of control and precision, ensuring that operations run smoothly and efficiently. This technological edge is particularly beneficial for industries that require stringent environmental controls, such as pharmaceuticals and food storage.

Versatility and Industry Applications

Air-inflated warehouses are highly versatile and can be adapted to a wide range of industry applications. They have been successfully implemented in sectors such as coal storage, pollution treatment, grain storage, logistics, and the steel industry. The adaptability of these structures allows them to meet the specific needs of different industries, offering customized solutions that enhance operational efficiency. For example, in the steel industry, air-inflated warehouses can provide a controlled environment that protects raw materials from weather-related damage. In logistics, their quick deployment and scalability make them ideal for managing fluctuating inventory levels. The ability to tailor these warehouses to diverse industry requirements demonstrates their broad applicability and effectiveness in various operational contexts.

In conclusion, air-inflated warehouses represent a significant advancement in the logistics and warehousing industry. Their architectural flexibility, cost-effectiveness, environmental sustainability, advanced monitoring capabilities, spatial adaptability, safety features, ease of relocation, material advantages, intelligent control systems, and wide-ranging industry applications make them a highly attractive option for businesses. By adopting air-inflated warehouses, companies can achieve greater efficiency, responsiveness, and sustainability, positioning themselves for success in an increasingly dynamic and competitive market.